|

|

Coagulation magnetic separation technology2022-08-28 10:40

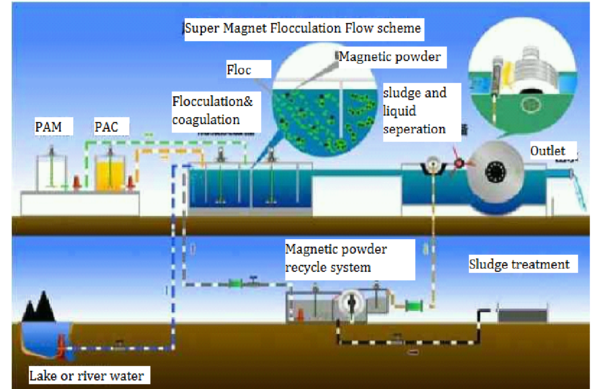

Coagulation magnetic separation technology (also known as rare earth disk separation water purification technology) uses patented magnetic seed processing technology, demagnetization technology, micromagnetic flocculation technology, dispersion technology and so on. Compared with traditional coagulation sedimentation and air flotation, this technology has the characteristics of continuous operation, high efficiency and rapid separation of suspended solids and colloids that are difficult to settle in water, and has the advantages of good treatment effect, short process, less land occupation, low investment and low operation cost. Especially, it has great advantages in the treatment of black and odorous water bodies such as rivers and lakes and the improvement of landscape water quality. Micro-magnetic flocculation technology Suspended solids and colloidal substances in wastewater generally do not have magnetism, Micromagnetic flocculation technology is to add magnetic seeds treated by special process to the water to be treated, With this magnetic seed as the "condensation nucleus", a small amount of coagulant and coagulant aid are added, so that pollutants such as nonmagnetic suspended solids, colloidal substances, phosphate and the magnetic seed can be quickly condensed into tiny magnetic flocs, which can be cleaned and separated under the strong magnetic force of rare earth disk separator, and the magnetic seed can be recycled after being treated by recovery process. Core of micro-magnetic flocculation technology A. Magnetic species: magnetic species processed by patented technology, with proper particle size and good dispersion, is conducive to the combination of pollutants such as non-magnetic suspended solids in water and magnetic species; B, nonmagnetic suspended solids and colloidal substances in water are combined with magnetic seeds put into water in the early stage under the action of a small amount of coagulant and coagulant aid, and can be separated under the action of strong magnetic field of rare earth permanent magnet separation and purification equipment only by microflocculation, without forming large flocs, with less dosage and short treatment time. Advantages of coagulation magnetic separation technology 1. Short hydraulic retention time. Magnetic separation is dozens of times faster than mechanical separation, which can realize the rapid separation of pollutants and water in water, and it only takes about 3 minutes from reaction to separation of suspended solids; 2. Small floor area. The reduction of residence time greatly reduces the volume of treatment equipment, thus greatly reducing the floor area; 3. Large amount of water is treated. A single device can achieve a processing capacity of 1000m3/h; 4. The sludge yield is low, the water content is low, the sludge is dense and easy to dehydrate, the wet sludge yield is about 0.5 ~ 1 ‰ of the treated water, and the water content of the sludge is 95 ~ 96%; 5. The effluent quality is good. The concentration of suspended solids in the treated effluent of the equipment is lower than 5mg/L, and the total phosphorus is lower than 0.1 mg/L; 6. Low operating cost. As an innovation to the conventional coagulation and sedimentation process, besides saving 1/3 of the chemical cost, the power consumption cost of the equipment itself is extremely low, and the power consumption per ton of water treatment is less than 0.03 yuan, which has great advantages in energy consumption.

|