|

|

Multi-stage A/O (MBBR-BAF) biofilm process with staged influent2022-08-28 11:43

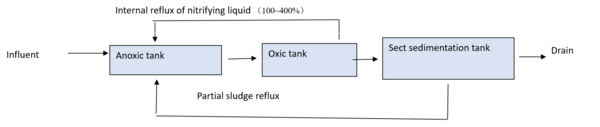

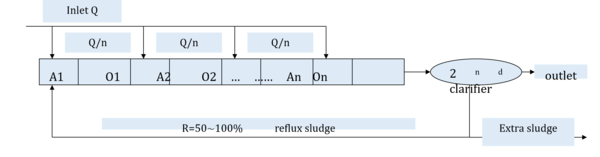

Why do you want to enter water in sections? The traditional A/O biological denitrification process is predenitrification, which returns the sewage rich in nitrate nitrogen at the end of aerobic tank to the front end, and uses the agents in raw water to denitrify, so as to effectively save the external carbon source. In order to obtain higher denitrification rate, the internal reflux ratio must be increased, but some nitrification solution can not be returned to the front end for denitrification, and the consumption of electric energy is greatly increased. The multistage A/O process with segmented influent belongs to the category of postdenitrification in form, and the carbon source comes from the sewage itself, so there is no need to set internal reflux in theory. In terms of denitrification mode, except for the terminal An section, other mixed liquids participate in the denitrification process, which can save energy consumption and obtain higher denitrification rate and more thorough denitrification. Traditional A/O biological nitrogen removal process

Multi-stage A/O process with segmented water inflow

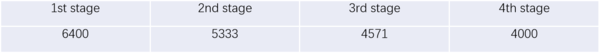

Characteristics of segmented water inflow process 1. High nitrogen removal efficiency: η = (1-1/N × 1/1 + r) ×% N is the number of segments; R is sludge reflux ratio. When the fourstage influent A/O process is adopted, the nitrogen removal efficiency is 87.5% (sludge reflux ratio is 100%, and there is no internal reflux), while the nitrogen removal efficiency is only 83% when the internal reflux is 400% in the traditional pre-denitrification process. 2. The average sludge concentration is high: Because sewage enters the reactor in sections, the dilution of the returned sludge is delayed, and the sludge concentration gradient is formed in space. The sludge concentration in the first few sections is significantly higher than the design value of conventional activated sludge, and it is the same as that in the conventional process when it flows into the secondary sedimentation tank. This reaction characteristic makes the biological reaction tank form high sludge concentration and low substrate concentration in local space under the condition of constant total sludge and solid load of secondary sedimentation tank, which reduces sludge load and makes pollutant degradation more thorough. To achieve the same treatment effect, the total volume of the pool can be reduced and the investment can be saved. Taking fourstage A/O inflow as an example, if the sludge concentration is 8000mg/L and the sludge reflux ratio is 100%, the sludge concentration in each stage is mg/L

The average sludge concentration of the system reaches 5076mg/L, which is 27% higher than that of the conventional process 4000mg/L under the same condition. 3. Energy saving and consumption reduction: The multi-stage A/O process with staged influent adopts post-denitrification process to remove nitrogen, which cancels internal reflux and has three advantages: A large amount of dissolved oxygen brought in by internal reflux is avoided, the treatment effect of anoxic zone is ensured, the denitrification process is thorough, and the nitrogen removal efficiency is improved; The energy consumption of internal reflux is saved; The carbon source in the sewage can be fully utilized from the anoxic zone, which can save the carbon source significantly for the municipal domestic sewage with low carbon-nitrogen ratio. Moving bed biofilm reactor MBBR By adding a certain amount of suspended carrier into the reactor, the biomass and biological species in the reactor are improved, thus improving the treatment efficiency of the reactor. Because the density of filler is close to that of water, it is completely mixed with water during aeration, and the environment for microbial growth is gas, liquid and solid. The impact and shear of the carrier in water make the air bubbles smaller and increase the utilization rate of oxygen. In addition, each carrier has different biological species inside and outside, with some anaerobic or facultative bacteria growing inside and aerobic bacteria outside, so that each carrier is a microreactor, so that nitrification reaction and denitrification reaction exist at the same time, thus improving the treatment effect. Main Characteristics of MBBR MBBR process has the advantages of both traditional fluidized bed and biological contact oxidation, Is a new and efficient sewage treatment method, The carrier is in a fluidized state by the aeration in the aeration tank and the lifting action of water flow, and then forms suspended activated sludge and attached biofilm, which makes the moving bed biofilm use the whole reactor space, giving full play to the advantages of attached phase and suspended phase organisms, and making them complement each other. Different from previous fillers, suspended fillers can come into contact with sewage frequently and many times, so they are called "moving biofilms". The key of moving bed biofilm reactor (MBBR) technology lies in the research and development of biological fillers with specific gravity close to water and easy to move freely with water under slight stirring. It has the characteristics of large effective specific surface area, suitable for microbial adsorption growth, strong applicability and wide application range, which can be used for organic matter removal, nitrogen and phosphorus removal as well; It can be used not only for newly built sewage treatment plants, but also for process transformation and upgrading of existing sewage treatment plants. Advantages of MBBR process (1) The volume load is high, compact and landsaving, especially for the upgrading and reconstruction of existing sewage treatment plants (facilities). Without increasing the land area, only the existing facilities need to be simply reconstructed, the sewage treatment capacity can be increased by 2-3 times, and the effluent quality can be improved. (2) Strong impact resistance, stable performance and reliable operation. The impact of impact load and temperature change on moving bed process is far less than that on activated sludge process. When the composition of sewage changes or the toxicity of sewage increases, biofilm has a strong tolerance. (3) The stirring and aeration system is easy to operate and maintain. The aeration system adopts perforated aeration pipe system, which is not easy to block. The mixer adopts bananashaped mixing blades, which have soft contour lines and do not damage the packing. The whole mixing and aeration system is easy to maintain and manage. (4) There is no blockage in the biological pool, the volume of the biological pool is fully utilized, and there is no dead angle. Because the packing and water flow can be mixed in the whole volume of the biological tank, the possibility of blockage of the biological tank is fundamentally eliminated, so the tank capacity is fully utilized. (5) Flexible and convenient. The flexibility of process is reflected in two aspects. On the one hand, various pool types (depth and depth can be used in Fiona Fang) can be adopted without affecting the treatment effect of the process. On the other hand, different filling ratios can be selected flexibly to meet the requirements of high efficiency and longterm expansion of treatment scale without increasing tank capacity. For the transformation and upgrading of the original activated sludge treatment plant, moving bed biofilm process can be conveniently combined with the original process to form activated sludge-biofilm integrated process or fluidized bed activated sludge combined process. (6) Long service life. Highquality and durable biological packing, aeration system and water outlet device can ensure the longterm use of the whole system without replacement and low depreciation rate. Highlights and Innovations of MBBR Technology 1. A biohydrophilic polymer material is introduced to improve the adsorption probability of pollutants. Because there are a large number of hydrophilic groupsOH (hydroxyl group) on the surface of the material, they can associate with water molecules by hydrogen bonds, thus improving the hydrophilicity of the filler and improving the contact probability between wastewater and biofilm attached to the filler. 2. Introduced the substance of improving biological activity, not only provided the proper nutrient source for the microorganism, but also improved the hydrophilicity of the filler, made it easier for the microorganism to grow, accelerated the startup of the biofilm and improved the efficiency of sewage treatment. 3. The magnetic powder of barium ferrite containing rare metals is introduced, and the filler after magnetization forms microscopic strong magnetic field and macroscopic weak magnetic field. Through the action of magnetic field, the osmotic pressure of water and the concentration of dissolved oxygen in water can be increased, which is beneficial to the transfer and diffusion of substances and the absorption and utilization of oxygen by microorganisms; At the same time, the enzyme oxidation reaction and freedom of the system were accelerated.Base reaction, etc.;Magnetic effect can also induce enzyme activity and enzyme synthesis, promote microbial growth, membrane formation and metabolism, and improve the permeability of microbial cell membrane. Enhance the activity of microorganisms and biological enzymes, strengthen the adsorption of degrading bacteria on the surface of the packing, and then improve the filmforming speed of the packing in wastewater treatment and the degradation speed of wastewater. 4. Active calcium was introduced as filler, which significantly improved the mechanical properties of polymer filler, especially the impact strength and toughness; 5. In order to further improve the dispersion of additives and prevent aggregation, active calcium and barium ferrite magnetic powders are mixed and processed with other components after chemical coating surface modification. The modified inorganic powder material is uniformly distributed inside and on the surface of the filler, which makes the service performance of the product more stable. Biological aerated filter (BAF) Biological Aerated Filter (BAF) is a new type of high-load submerged three-phase reactor, which has the advantages of both activated sludge process and biofilm process. Biological aerated filter is a deformation form of common biological filter, It can also be regarded as a special form of biological contact oxidation, That is, the bioreactor is filled with granular fillers with high specific surface area (which can be ceramsite filter media or volcanic rock filter media), To provide a carrier for microbial membrane growth, And divide into downward flow or upward flow according to different flow direction of sewage, The sewage flows into the filter material layer, and the lower part of the filter material layer is blast and aeration to make the air contact with the sewage, so that the organic matter in the sewage and the biofilm on the surface of the filler can be degraded through biochemical reaction. The filler also plays a physical filtration role, intercepting the suspended solids and the fallen biofilm in the sewage, and regularly carrying out backwashing to restore the filtration function. Characteristics of BAF Process

1.Introduced a biological hydrophilic polymer material which can increase the adsorption probability of pollutants. Since a large amount of hydrophilic groups -OH (hydroxyl groups) exist on the surface of the material, they can be hydrogen-bonded with water molecules to improve hydrophilic of the filler,which increases the chance of contact of the sewage with the biofilm attached to the filler. 2.Introduced biologically active substances.This substance not only provides a suitable source of nutrients for the microorganisms, but also improves the hydrophilicity of the filler,and is beneficial for microbial growth, speed up the biofilm forming start and improve sewage treatment efficiency. 3. The introduction of active calcium in biofiller.It significantly modified the mechanical properties of the polymer filler, especially impact strength and toughness; 4. In order to further improve the dispersibility of the additive and prevent agglomeration, the active calcium and barium ferrite magnetic powders are chemically coated and modified, and then mixed and processed with other components. The modified inorganic powder material is evenly distributed inside and on the surface of the filler, so that the product performance is more stable. 5. Introduced barium ferrite magnetic powder containing rare metals.The magnetically processed filler forms a microscopic strong magnetic field and a macroscopic weak magnetic field. Through the action of the magnetic field, the osmotic pressure of water and the concentration of dissolved oxygen in water can be increased, which is beneficial to the diffusion of substances and the absorption and utilization of oxygen by microorganisms. At the same time, the enzyme oxidation reaction and free radical reaction of the system are accelerated; It induces the enzyme activity and enzyme synthesis of microorganisms, promotes the growth of microbial growth membranes and metabolism, and also improves the permeability of microbial cell membranes. Improve the activity of microorganisms and biological enzymes, strengthen the adsorption of degrading bacteria on the surface of the filler, and thereby improve the bio-film forming speed in the sewage treatment and the degradation rate of the sewage.

|